1. Layin da ya dace

Wannan littafin ya shafi shigar da na'urar jigilar sarkar aluminum mai sassauƙa

2. Shirye-shirye kafin shigarwa

2.1 Tsarin shigarwa

2.1.1 Yi nazarin zane-zanen haɗuwa don shiryawa don shigarwa

2.1.2 Tabbatar cewa ana iya samar da kayan aikin da ake buƙata

2.1.3 Tabbatar cewa duk kayan aiki da kayan da ake buƙata don haɗa tsarin jigilar kaya suna nan, sannan a duba jerin sassan

2.1.4 Tabbatar cewa akwai isasshen sarari a ƙasa don shigar da tsarin jigilar kaya

2.1.5 Duba ko ƙasan wurin shigarwar ta yi lebur, ta yadda za a iya ɗaukar dukkan ƙafafun tallafi a saman ƙasan.

2.2 Jerin shigarwa

2.2.1 Saƙa dukkan katako zuwa tsawon da ake buƙata a zane

2.2.2 Haɗa ƙafafu da katakon tsari

2.2.3 Shigar da sandunan jigilar kaya kuma sanya su a kan tsarin tallafi

2.2.4 Shigar da na'urar tuƙi da na'urar Idler a ƙarshen na'urar jigilar kaya

2.2.5 Gwada wani sashe na na'urar jigilar sarka, duba don tabbatar da babu cikas

2.2.6 Haɗa kuma shigar da farantin sarkar a kan na'urar jigilar kaya

2.3 Shirye-shiryen kayan aikin shigarwa

Kayan aikin shigarwa sun haɗa da: kayan aikin saka fil na sarka, makulli mai siffar hex, makulli mai siffar hex, da kuma rawar bindiga.

2.4Sassa da kayan shiryawa

Maƙallan da aka saba amfani da su

Gyada mai zamiya

Goro mai murabba'i

goro mai bazara

Layin haɗi

3 Taro

3.1 sassan

Tsarin jigilar kaya na asali za a iya raba shi zuwa ƙungiyoyi biyar masu zuwa

3.1.1 Tsarin tallafi

3.1.2 Gilashin jigilar kaya, sashin madaidaiciya da sashin lanƙwasa

3.1.3 Na'urar tuƙi da na'urar rashin aiki

3.1.4 Sarka mai sassauƙa

3.1.5 Sauran kayan haɗi

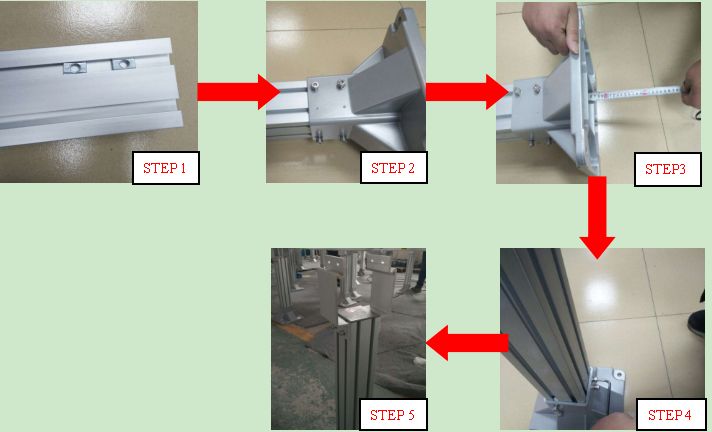

3.2 Hawan ƙafa

3.2.1 Sanya goro mai zamiya a cikin ramin T na katakon tallafi

3.2.2 Sanya maƙallin tallafi a cikin farantin ƙafa, sannan a gyara goro mai zamiya da aka sanya a gaba ta hanyar sukurori masu kusurwa huɗu, sannan a matse shi cikin 'yanci

3.3.1 Daidaita katako daga ƙasan ƙafa zuwa girman da zane ya buƙata, wanda ya dace da daidaita tsayi a cikin taro na gaba

3.3.2 Yi amfani da maƙulli don ƙara matse sukurori

3.3.3 Shigar da firam ɗin tallafi na katako ta hanyar shigar da farantin ƙafa

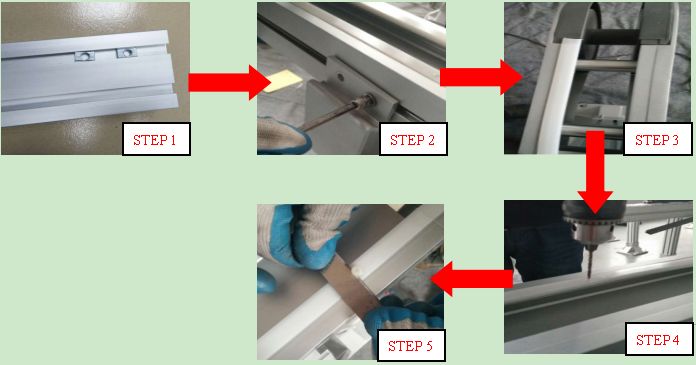

3.3 Shigar da katakon jigilar kaya

3.3.4 Sanya goro mai zamiya a cikin ramin T

3.3.5 Da farko gyara maƙallin farko da kuma sandar jigilar kaya, sannan a ja maƙallin na biyu a matse shi da sukurori.

3.3.6 Fara daga ɓangaren na'urar Idler, danna tsiri mai lalacewa a cikin wurin shigarwa

3.3.7 Naushewa da kuma taɓawa a kan layin da aka sa

3.3.8 Sanya goro na filastik sannan a yanke ƙarin ɓangaren da wuka mai amfani

3.4 Shigarwa da cire farantin sarka

3.4.1 Fara shigar da farantin sarkar bayan an gama haɗa kayan aikin, . Da farko, cire farantin gefe a gefen sashin ladler, sannan a ɗauki wani ɓangare na farantin sarkar, a sanya shi daga sashin ladler zuwa cikin katakon jigilar kaya, sannan a tura farantin sarkar don ya gudana tare da katakon jigilar kaya don da'ira. Tabbatar cewa taron jigilar kaya ya cika buƙatun

3.4.2 Yi amfani da kayan aikin saka fil ɗin sarka don haɗa faranti na sarka a jere, kula da matsayin ramin beads na nailan zuwa waje, sannan a danna fil ɗin ƙarfe a cikin farantin sarka don ya kasance a tsakiya. Bayan an haɗa farantin sarka, a sanya shi a cikin katakon jigilar kaya daga sashin ladle, a kula da farantin sarka Alkiblar jigilar kaya.

3.4.3 Bayan farantin sarkar ya naɗe a kan hanyar jigilar kaya don yin da'ira, a matse kan da wutsiyar farantin sarkar don kwaikwayon yanayin kayan aikin bayan haɗawa (bai kamata ya yi sassauƙa ko ya yi tsauri sosai ba), a tabbatar da tsawon farantin sarkar da ake buƙata, sannan a cire farantin sarkar da ta wuce gona da iri (ba a ba da shawarar a sake amfani da beads na nailan ba)

3.4.4 Cire Idler sprocket kuma yi amfani da kayan aikin saka sarkar fil don haɗa ƙarshen farantin sarkar zuwa ƙarshe

3.4.5 Shigar da Idler sprocket da farantin gefen da aka wargaza, kula da cewa ya kamata a haɗa tsiri mai jure lalacewa a kan farantin gefen a wurinsa, kuma babu wani abin ɗagawa da zai iya faruwa.

3.4.6 Lokacin da aka shimfiɗa farantin sarkar ko kuma wasu dalilai da ake buƙatar cirewa, matakan aiki suna komawa ga tsarin shigarwa

Lokacin Saƙo: Disamba-27-2022